At Pile Vic, we’ve been in the groundworks game long enough to see the best and the worst of what the industry offers. We’ve built foundations that last, literally and metaphorically.

In that process, we’ve come face-to-face with a harsh truth: Too many clients choose the wrong piling contractor and pay for it down the line.

This article isn’t a pitch. It’s a warning.

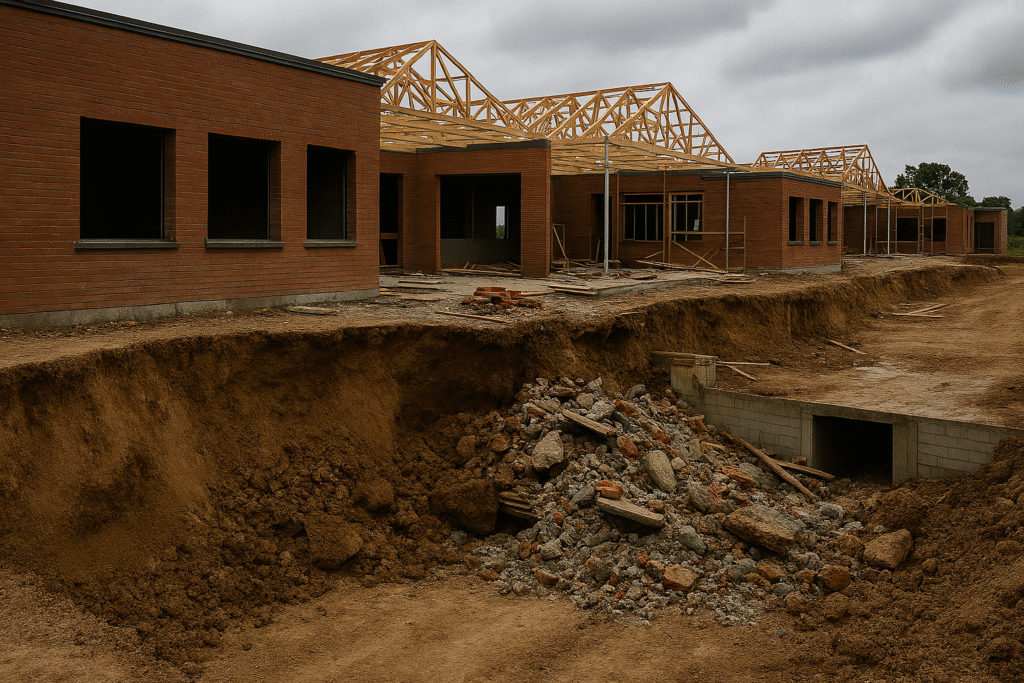

Planning to build something that matters? A structure that will stand the test of time? Then the first mistake is underestimating what goes into the ground.

Our goal is simple: Expose the signal in the noise. Once you know what to avoid, the right choice becomes obvious.

The following are the Top 5 Mistakes we see clients make when choosing a piling contractor, stripped down to their core mechanics (just between me and you).

Mistake #1: Choosing Based on Price Alone

What is the goal? A safe, durable, code-compliant foundation.

What does it require? Proper design, soil understanding, materials, equipment, skill.

What does rock-bottom pricing usually omit? One or more of the above.

Cheap piling is often just deferred expense. Either in rectification works, delays, or legal risk. A low quote with no soil testing, vague inclusions, or hidden exclusions is not a bargain — it’s a liability trap.

Ask yourself: How is the contractor achieving that price? Are they using thinner steel? Skipping inspections? Rushing install times with underqualified labour?

There is always a compromise — and if it isn’t disclosed upfront, it will appear later as a structural failure, a legal issue, or a builder’s variation claim. The piling is what everything else rests on. Cutting corners here is like laying unstable foundations for your entire budget.

Mistake #2: Ignoring Ground Conditions and Site-Specific Design

- All soil is not equal. The behaviour of clay, sand, silt, rock — completely different.

- Correct piling is engineered, not guessed.

- Generic designs = generic disasters.

If a contractor doesn’t demand a soil report or perform a site inspection, they’re operating blind. You wouldn’t accept a surgeon skipping your diagnosis. Why allow it in construction?

Designing a pile system without understanding the site is reckless. Some sites require deeper embedment, corrosion protection, or pre-drilling.

Others may need rock sockets or different pile types altogether. If a contractor offers a one-size-fits-all solution, what they’re really offering is negligence disguised as confidence. The ground is telling you what it needs — your contractor should be listening.

Mistake #3: Overlooking Licensing, Engineering Sign-Off and Insurance

- What’s the real job? Not just driving steel into the ground, but certifying safety and compliance.

- Without licenses and engineering, there is no accountability.

- Without insurance, you bear the full risk.

Many cowboys operate without full licensing, or sign-offs are retrofitted post-installation. This is backwards. Engineering integrity cannot be an afterthought.

You need to ask: Who is taking responsibility for the design, the installation and the long-term integrity of the system? If it’s not a qualified engineer, and if the contractor isn’t insured to do the work, then the liability falls back on the builder or client. That’s not just risky — it’s negligent. Compliance isn’t paperwork. It’s the evidence that your structure has been built with discipline.

Mistake #4: No Transparency in Inclusions and Scope

- Construction works are chains of dependencies. If the piling contractor’s scope is unclear, downstream problems are guaranteed.

- Hidden exclusions = unexpected invoices.

Quotes that don’t clarify if spoil removal, pile caps, concrete, or crane access are included… are booby-traps. Clarity is a feature, not a luxury.

When scopes are vague, everyone assumes something different. You think the pile caps are included. The contractor thinks they’re not. You assume they’ll remove spoil. They assume someone else will.

These misunderstandings lead to variations, cost blowouts and project delays. A good contractor eliminates ambiguity. A bad one profits from it.

Mistake #5: No Track Record in Similar Conditions or Projects

- What matters more than experience? Relevant experience.

- Every piling method has constraints, from helical screw piles to bored piers.

- Previous success ≠ future success without matching context.

Don’t hire someone who’s done “piling before.” Hire someone who’s done your kind of piling — same soil type, same load requirements, same build conditions.

There’s a difference between a contractor who has done piling and one who understands your specific project requirements. You wouldn’t hire a marine piling specialist for a residential hillside site. Yet many contractors use previous jobs as false credentials.

Ask to see relevant case studies. Check what challenges they faced and how they solved them. It’s not about showing up with a rig — it’s about showing up with the right expertise.

Wrapping Up…

Choosing the right piling contractor isn’t just a matter of logistics — it’s a strategic decision that sets the tone for your entire project. Every mistake outlined above can lead to cost blowouts, timeline disruptions, or even structural failure. Don’t gamble on the most critical part of your build. Get it right from the ground up.

Ready to Build with Confidence?

At Pile Vic, we don’t cut corners. We engineer certainty. With years of experience, a proven track record across Victoria, and an uncompromising approach to quality, we deliver piling solutions that stand the test of time.

Get in contact with Pile Vic today and find out how we can set the foundation for your next successful project!